Should you ship your products directly to retail stores and bypass the go-between, or is there something to be said for letting your retail partners own the distribution to individual stores?

This is a question every brand and manufacturer has to contend with at some point. They have to make a decision between Direct Store Delivery or centralized distribution through retailers’ supply chains. This decision can have a massive impact on costs and supply chain efficiency. Understanding the stakes is critical as you make your decision.

Let’s take a look at what Direct Store Delivery is, how it compares to a warehousing model, and how you can decide which is right for you.

What is Direct Store Delivery?

Direct Store Delivery, or DSD, is a method of retail distribution where manufacturers ship merchandise directly to a retailer via a distributor.

In the DSD model, products will bypass the retailer’s distribution center. Instead, the distributor checks the inventory, stores the merchandise, stocks the shelves, sets up in-store displays, displays pricing, and other key tasks. The retailer itself doesn’t have to worry about any of those tasks in this model.

DSD is most prominent in retail verticals that sell fast-turnover, high-volume products with consistently high consumer demand. The faster time-to-market is a benefit because you can get goods into your shoppers’ hands more easily, preventing the negative effects of out-of-stocks.

The grocery industry, in particular, relies on DSD because it deals with a lot of perishable products. Getting perishable items directly to store shelves without having to go through warehousing is crucial for these supply chains because it’s much faster and more efficient. Other verticals, such as consumer goods, can also benefit from the Direct Store Delivery model.

Direct Store Delivery, or DSD, is a method of retail distribution where manufacturers ship merchandise directly to a retailer via a distributor.

Direct Store Delivery vs. Warehousing

Direct Store Delivery is often compared to a centralized distribution approach. This model is where a manufacturer or brand ships its product to a retailer’s distribution center or warehouse, and the retailer is responsible for getting the goods from there to its store locations.

One of the core benefits of a centralized delivery model is that smaller brands that can’t afford the overhead that comes with managing a DSD fleet can still get their products to market. DSD makes your supply chain much more complex because it impacts everything from forecasting and inventory management to pricing and in-store merchandising.

The warehousing model can also lower costs because the retailer handles the last mile distribution. For large retailers, economies of scale also come into play with high volumes. Instead of doing direct-to-store shipments for individual stores across a large geographical area, it often makes more sense to work with a centralized distributor.

The warehousing model does have some drawbacks, including:

More handling of products—If you’re shipping your products to a warehouse, and the retailer is then shipping them to their stores, that’s more chances you’re taking where products can get lost or damaged in transit. Fragile products are at a disadvantage here.

Potential higher costs for the customer—The more players involved in a supply chain, the more expensive the end product is for the customer. If you’re in a low-cost, high-volume category, this incremental price increase could lose you customers.

Potentially slower time-to-market—In the warehousing model, you’re relying on the retailer to keep your products on shelves and displayed correctly. Interruptions or mistakes on the part of individual store managers could lead to a lack of availability for your customers.

How to Choose Between Direct Store Delivery or Warehousing

Choosing a DSD model or a central distribution model doesn’t have to be a binary decision. Many brands use both for different types of products. If you’re trying to decide which one makes sense for your logistics, here are some key questions you should ask.

Do Regulations Apply?

In the case of some products, DSD may be the only viable model due to regulations around freshness. For products like milk, bread, beer, and other fast-to-spoil goods, DSD is essential. You can’t have these products sitting in a warehouse for days or weeks before a store manager orders them.

In the examples here, some states have regulatory mandates for these categories. Failure to adhere to these regulations could lead to fines and other legal issues.

This only applies in fairly specific cases, and it’s usually not something non-grocery retailers have to worry about. That said, it’s important to understand the regulations that come into play with your products in your retailers’ locations.

How Does Seasonality Come into Play?

For seasonal products, demand often spikes during a set time period. This is a situation where speed is critical. You want to be able to get your products on shelves quickly to ensure your customers can find you. A DSD model is most effective here.

Beyond that, the in-store experience matters. By controlling the in-store merchandising, pricing, and shelving, you can set yourself up for success by displaying your products in the best way possible during a demand spike.

What’s Best for Your Products?

Certain kinds of products lend themselves to different methods of distribution. Some products may require DSD. With ice cream, fresh eggs, and dairy, for example, retailer warehouses may not have the facilities to store fresh or frozen products for a period of time, so they need to be delivered directly to the store to reduce spoilage.

Other products are fragile, like bread and potato chips. These are so easily crushed—and therefore usually unsellable—that it only makes sense to reduce the number of people and machines handling them.

You have to determine what’s best for your particular products when comparing DSD and centralized distribution. Here are some specific product characteristics that you should consider when deciding:

Products that require high supplier knowledge. — With DSD, you have more control over how your products are priced and displayed. Retailers may not have specific knowledge about your products, particularly in specialty goods, so it’s worth investing in a DSD program that doesn’t leave your messaging up to a non-expert.

Products that require special handling. — Oddly shaped, fragile, or temperature-controlled products may not be suitable for a retailer that doesn’t have the means to transport and store those goods. If your products don’t have these requirements, a warehousing approach might work, but if they do, you’ll want more oversight on logistics to avoid losses.

Products with short shelf lives. — If your product can only be on the shelf for a short time, whether it’s due to potential spoilage or a short lift in seasonal demand, you need to be able to bypass the traditional retail distribution channel and get your items directly on the shelf.

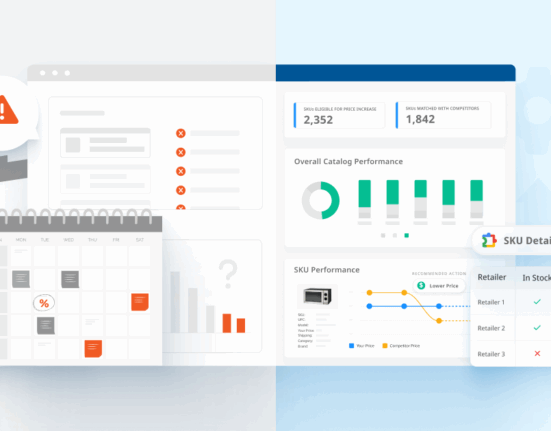

Do DSD Costs at Scale Make Sense for You?

DSD can add some significant labor costs for a brand. Distributing goods directly to retailers means you have to employ a large number of drivers, merchandisers, and distribution center staff.

According to a report from Retail Wire, some major CPG brands are dumping the DSD model in favor of centralized distribution.

Nestlé is just one major U.S. brand that is scrapping its DSD program and is instead shipping all of its products to retailers’ distribution centers. The retailers will be responsible for getting Nestlé’s products to their stores.

The primary reason for this move was to avoid duplicate costs in the distribution structure. Steve Presley, CEO of Nestlé USA, said that the DSD model was too expensive because the brand was incurring the costs of its own DSD program, while retailers and other vendors were also making store deliveries. The process had too many redundancies.

Brands like Kellogg and Hostess have made similar decisions, per Retail Wire’s report.

In a similar fashion, you should look at your DSD costs and see if your brand is facing similar duplicative costs. If freshness isn’t a major factor, going with a warehousing model might be more cost-effective at scale.

The big question to ask yourself when considering this supply chain issue is: Are we creating efficiencies and making both ourselves and the retailers more money?

There’s no right or wrong answer when deciding between Direct Store Delivery and warehousing/central distribution. It’s all about understanding your products, your goals, and what your retail partners are capable of—then, making the decision that best suits your brand.