Across nearly every retail vertical, companies are faced with pressure from regulators and consumers to provide more visibility into their supply chains.

If you’re in this space, chances are you’re well-aware of the push for greater transparency, which stems from better traceability. The food and pharmaceutical industries are already very familiar with standards around traceability, as consumer safety hinges on manufacturers’ and distributors’ ability to track and trace every ingredient.

But it’s not just companies in those spaces looking to improve supply chain traceability and transparency.

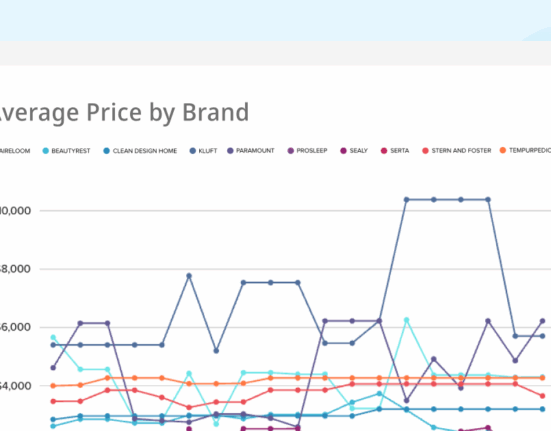

As the market for counterfeit and pirated goods grows, manufacturers and retailers in verticals such as apparel, electronics, cosmetics, and beyond need to make every effort to ensure only legitimate products are on the market. According to the OECD, trade in counterfeit goods rose to 3.3 percent of all global trade, with footwear, clothing, electrical equipment and medical equipment making up some of the most common items in that illicit trade.

For practical purposes, traceability is the infrastructure and processes built for tracking the journey of products and all of their inputs through a supply chain from raw materials to the moment a consumer purchases the end product.

As difficult as it is to implement traceability best practices throughout the entire supply chain, the benefits can be far-ranging. It’s crucial for retailers because it ensures a consistent stream of data that retailers can use to understand their supply chains, from sourcing and manufacturing to distribution and retail.

One of the most common ways to ensure traceability in the supply chain is through product serialization.

Product serialization is the process of tagging individual saleable units of inventory with unique identifiers that are assigned sequentially to each item.

What is Product Serialization?

Product serialization is the process of tagging individual saleable units of inventory with unique identifiers that are assigned sequentially to each item.

While it’s often discussed in terms of serial numbers, serialization doesn’t necessarily need to follow a strict numerical pattern.

You’ve probably seen serial numbers on many of the products you own. Jewelry, smartphones, musical instruments, computer hardware and software, household appliances, automobiles and many others all have unit-level serial numbers printed on them. For products with many different components and subassemblies, such as appliances or electronics, the individual components could also have their own serial numbers.

It’s worth clarifying some other terms that are closely related to serialization. In addition to their serial numbers, some products will also have model numbers. Model numbers are used to identify the model an item belongs to, not the individual unit.

A Stock Keeping Unit (SKU) is another way to track and trace items at the retailer level. This, however, has nothing to do with a specific saleable unit of an item—it’s a location-specific number and is only used at the store where it is being sold.

Serialization enables end-to-end traceability because it allows manufacturers and retailers to use human- and machine-readable codes to track products back to their origins, determine which supply chain partners handled the products or packaging, find the specific components or ingredients that went into the final product, and track the item’s overall history.

Benefits of Product Serialization

Product serialization benefits you in several ways, particularly when it comes to protecting your brand, your supply chain, and your customers. Here are just a few of the notable benefits:

- Prevent MAP violations – If you find that your items are being sold by an unauthorized retailer below your minimum advertised price, product serialization gives you a powerful tool in stopping them. A trap buy program will allow you to purchase your products from this unknown vendor, check the serial numbers of the products, determine which of your distributors was responsible for these products, and take the appropriate actions to remediate the situation.

- Improve quality control – Serialization makes quality control much easier. If you find defects in your QC process, you will be able to track the faulty products to their origin— the third-party suppliers used to source components—and even determine the date of manufacture to trace issues back to their root and prevent them from happening again.

- Ensure regulatory compliance – Tracking products through the supply chain can ensure that they meet the quality and safety standards of whatever regions of the world your products are sold in. Stopping counterfeits and stolen goods from reaching consumers is also a vital part of serialization and traceability that regulators will lean on manufacturers to handle.

- Make credible corporate responsibility claims – Brands that want to promote themselves as sustainable, carbon-neutral, fair trade, allergy-free, gluten-free, etc. must be able to provide credible proof that they adhere to those practices throughout their supply chains. Being able to track specific items and their packaging to their origins makes this possible.

- Improve recall management – Recalls are nightmares for manufacturers, but serialization allows for faster resolution. By understanding exactly which units have a defect, you can more easily trace them back through the supply chain and discover where the defect occurred, allowing you to fix the problem quickly.

Of course, going through the serialization process and deploying item-level traceability isn’t always appropriate for every product. Products that are low-cost, homogenous, aren’t subject to strict regulation or safety requirements, or otherwise don’t need to be traced to a particular user may not need to be serialized. For example, generic clothes or accessories and home decor will likely have a batch number, but not a unit-level serial number.

Serialization can have a massive impact on your ability to manage your supply chain, but it is not simply a matter of adding a number to your products or packaging. It must be looked at as part of your business strategy, something that requires operations, packaging, quality control, distribution, and IT to work together multi-directionally using a mix of digital technologies and human interventions to make it work.

The benefits of doing so, however, can provide your business with a means of improving operations, reducing regulatory and business-level risk, and better serving customers.